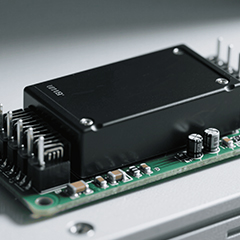

CMR Nanocrystalline Solution: With outstanding electromagnetic performance, it provides strong EMC protection, higher efficiency and power density, and unparalleled reliability for your products in complex electromagnetic environments, helping customers easily meet the most stringent global EMC standards and performance requirements.

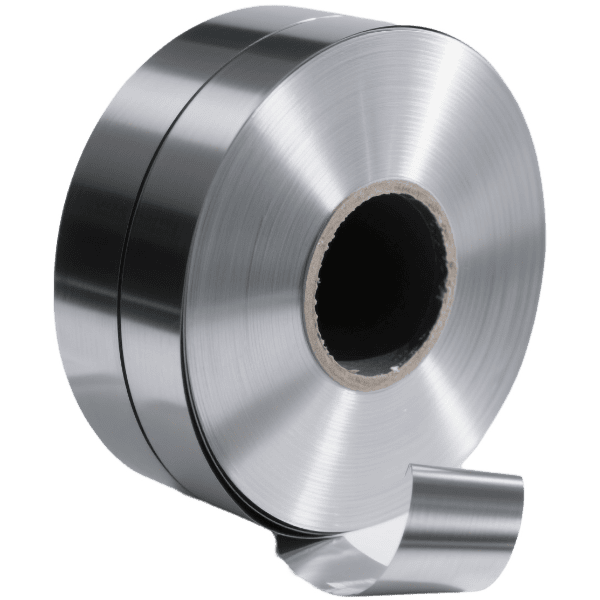

High-performance nano-crystalline alloy tape exhibits excellent magnetic properties and temperature stability

CMR can tailor exclusive formulations of nano-crystalline alloy tape based on clients' actual needs.

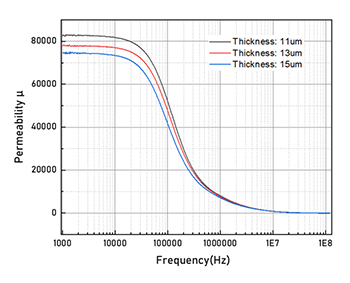

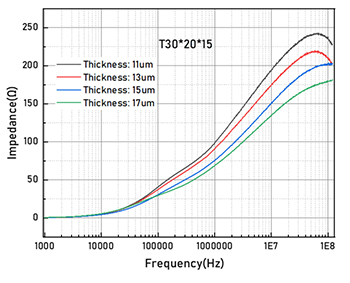

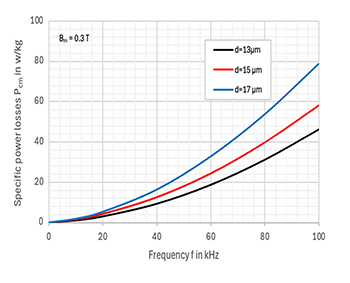

>8×10⁴, delivers high magnetic performance at medium and high frequencies

High resistivity improves high-frequency performance and reduces eddy current losses

<1.5A/m, enables fast core response and high efficiency

Less than 10% change in core performance within -55℃ to 150℃

Currently the soft magnetic material with the best overall performance on the market

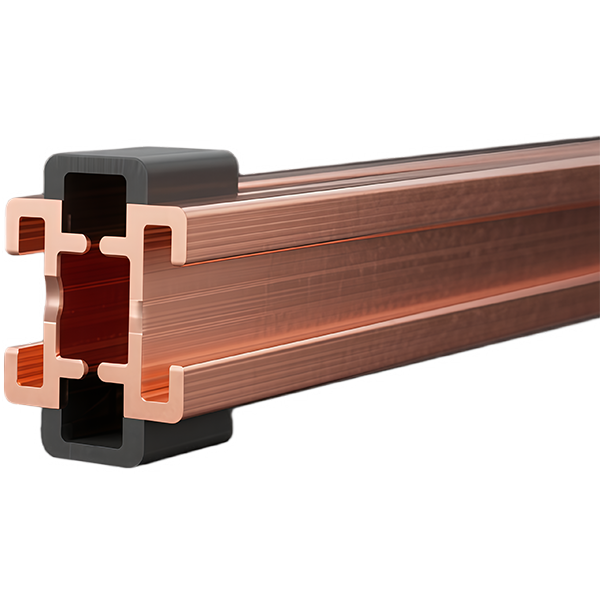

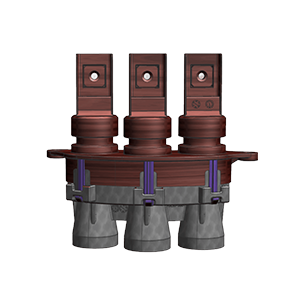

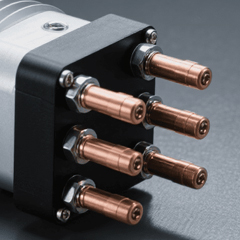

A manufacturing process that embeds copper busbars into plastic insulators via injection molding.

Busbar Insert Injection Molding

Technology

Busbar insert injection molding is a manufacturing technology that embeds copper conductive busbars into plastic insulators through injection molding process.

Automotive

New Energy

Consumer Electronics

Home Appliances

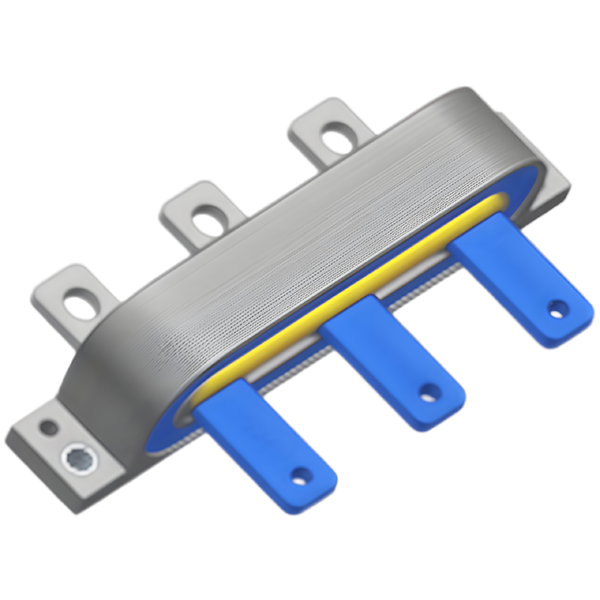

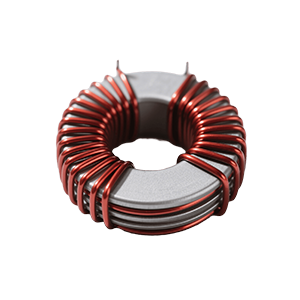

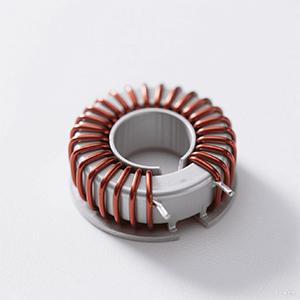

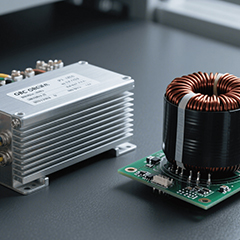

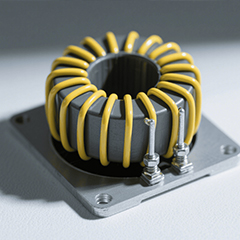

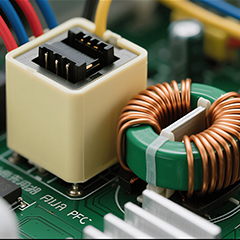

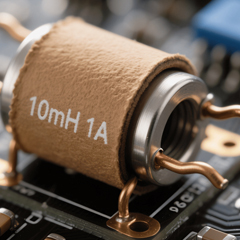

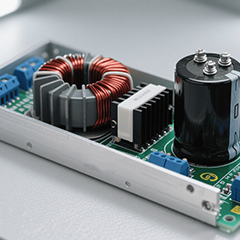

Inductors work with capacitors to achieve filtering and voltage stabilization.

High-frequency inductors are used in resonant circuits or impedance matching.

Power inductors undertake energy buffering and current smoothing functions.

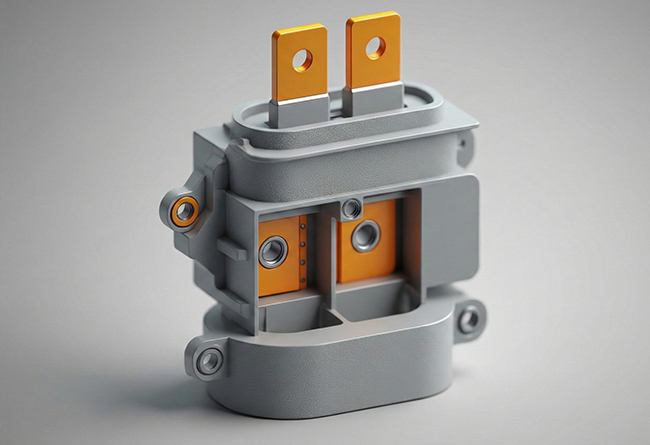

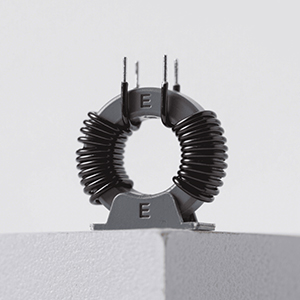

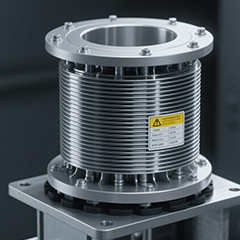

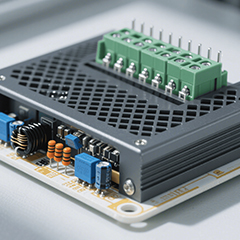

Electromagnetic Compatibility (EMC) Devices for Three Phase Power Systems

Miniature devices for integrating filtering circuits at electronic interfaces

In switching power supplies, inductors配合 capacitors to achieve filtering and voltage stabilization

In RF circuits, high-frequency inductors are used for resonant circuits or impedance matching

In motor drives, power inductors undertake energy buffering and current smoothing functions

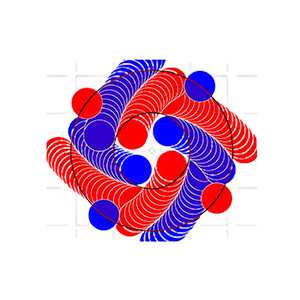

Achieve precise and efficient magnetic positioning,

as well as multi-position spring and door lock functions.

Program the polarity of defined magnets and provide a magnetic matrix.

Precision

Magnetic Force

Interference

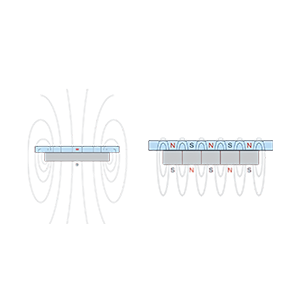

Programmable magnetization enables multiple positive/negative poles on the same surface. Magnetic pole minimum control within 2mm

Minimal magnetic interference: Complex magnetic circuit simulation design reduces magnetic interference to near-zero

Stronger attraction: Effective concentration of magnetic flux lines enhances吸引力 up to 3-5 times that of ordinary magnets

Versatile functions: Supports customized magnetization of magnetic steel to realize diverse functional requirements

CMR focuses on developing advanced EMC technology, offering innovative and reliable electromagnetic compatibility solutions for industries such as automotive, new energy, and power electronics, helping customers overcome complex electromagnetic environment challenges and ensure product performance and compliance:

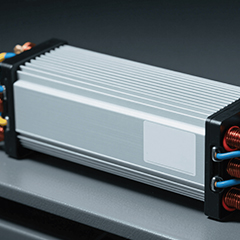

High power density and efficiency are core requirements for electric vehicles Wide operating temperature range (-40°C to +130°C or higher) meets automotive-grade requirements Excellent vibration resistance performance

High efficiency (low losses) is crucial for improving overall system energy efficiency High power density enables equipment miniaturization Excellent high-temperature stability adapts to outdoor or enclosed cabinet environments

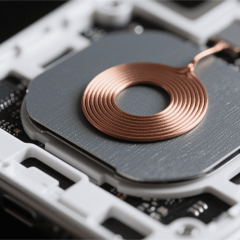

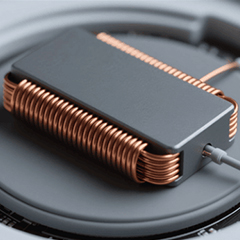

High magnetic permeability effectively guides and concentrates the magnetic field, improving charging efficiency and transmission distance. Low losses reduce heat generation. Ultra-thin strip materials (e.g., 18μm, 14μm) enable miniaturized and slim designs.

High reliability ensures long-term stable operation Low power consumption improves energy efficiency rating Compact design fits into tight spaces

Scan the QR code to follow our official account